Hello! I’m Peter, a veteran with over two decades of experience in China’s paper product export industry. Over the years, I’ve personally handled countless orders for custom paper bags, from initial client communication to the final product’s overseas journey. Every step has been full of challenges and joys. Today, I want to talk about custom personalized paper bags, sharing some insights that I hope will help business owners and event planners navigate the vast paper bag market, find the perfect one for their needs, and leave a lasting impression of their brand on consumers.

Why Choose Custom Personalized Paper Bags? – More Than Just Packaging, It’s Brand Extension

In my career, I’ve found that many clients initially only understand paper bags on a “packaging” level. But in reality, custom personalized paper bags are much more. They are a flowing business card, a silent salesperson, and a unique brand experience.

Imagine your customers walking out of your store carrying a custom printed paper bag with your brand logo and unique design. They’ve not only taken home a product, but also your brand story. This paper bag will constantly remind them of your presence on their way home, in their daily lives, and even on social media. A well-designed, high-quality custom bag can subtly enhance your brand image and increase customer loyalty.

I remember a few years ago, we customized a batch of paper bags for a high-end luxury brand. Their attention to detail was meticulous, from the paper’s gram weight and the handle material to the printing’s color saturation – they strived for perfection. Ultimately, when those beautifully embossed paper bags with ribbon handles reached the client, they were full of praise. Later, I learned from the client that many of their consumers even treasured or reused these bags, far exceeding our traditional definition of “packaging.” This made me deeply realize that the value of custom paper bags far exceeds their price.

So, how can you create such a practical and brand-rich custom paper bag? There’s a lot to learn.

I. Size, Paper, and Handles: Essential Elements of Custom Paper Bags

The first and most crucial step in customizing custom paper bags is determining their basic components: size, paper type, and handle type. This is like laying the foundation for a house; without a strong foundation, even a skyscraper can collapse.

1. Size: Your Product is the “Star,” the Paper Bag is the “Supporting Role”

I often tell clients that the golden rule for choosing paper bag size is: let the paper bag perfectly fit your product, not the other way around.

- Consider the size and shape of your product: This is fundamental. If your product is a shoe box, the paper bag’s width, height, and depth must easily accommodate the box with a little extra space. If your product is clothing, you might need a wider paper bag to prevent the clothes from being crushed.

- Consider the product weight: If the product is heavy, an oversized paper bag might lead to uneven stress and easily tear. Also, a too-large bag will feel cumbersome when carrying heavy items.

- Consider the usage scenario: Is it for retail packaging or event giveaways? For event giveaways, the size should not be too large for participants to carry conveniently.

- Reference common sizes: While custom-made, you can often refer to common sizes. For example, a common A4 document bag is approximately 32x26x10 cm (H x W x D), and a clothing store’s common size might be around 40x30x12 cm. Of course, these are just references; the final size needs to be determined based on your specific needs.

I once had a client who sold high-end red wine. Initially, they provided a very standard paper bag size but overlooked the special shape and weight of wine bottles. We advised them to adjust the size, deepen the bag, and increase the paper’s gram weight. Ultimately, the wine bottle sat securely in the bag, and the client was very satisfied with our professionalism.

2. Paper Type: The “Personality” of the Paper Bag is Determined by It

Paper is the “skeleton” of the paper bag; different paper types give the bag different textures and strengths. When choosing, you need to consider aesthetics, practicality, environmental friendliness, and budget.

- White Cardboard: This is one of the most commonly used papers. It has a smooth surface, excellent printing results, vibrant colors, and high stiffness. Typically, the gram weight is between 190-350gsm. It is suitable for various products, especially brands that need to display clear printing.

- My experience: White cardboard is a versatile choice; if you have no special paper preference, choose it. But remember, the higher the gram weight, the stiffer the bag, and the higher the cost.

- Coated Paper: It has a coated surface, good gloss, and high color reproduction in printing. Typically, the gram weight is between 157-300gsm. It is divided into gloss coated paper and matte coated paper.

- Gloss Coated Paper: Visually bright, suitable for brands that need to emphasize color.

- Matte Coated Paper: Softer texture, understated luxury, suitable for brands seeking a high-end feel.

- My experience: The printing effect of coated paper is undeniable, but be aware that its crease resistance is relatively weak; repeated folding might cause creases.

- Kraft Paper: Environmentally friendly, durable, available in natural kraft (brown) and white kraft paper. It has a unique natural vintage feel and strong load-bearing capacity. Typically, the gram weight is between 80-300gsm.

- Natural Kraft Paper: Suitable for brands pursuing an eco-friendly, minimalist, and natural style. Printing colors are mainly single or a few colors, which look best.

- White Kraft Paper: Retains the toughness of kraft paper while offering more printing space.

- My experience: Kraft paper has been a very popular choice in recent years, especially favored by environmentally conscious brands. Its load-bearing capacity is indeed excellent, but printing colors will be affected by the paper’s base color, making them less vibrant than white cardboard and coated paper.

- Specialty Paper: A wide variety, such as art paper, pearlescent paper, flocked paper, etc., with special textures, gloss, or tactile sensations, can greatly enhance the grade and uniqueness of the paper bag.

- My experience: While specialty paper is more expensive, it offers unparalleled visual and tactile experiences. If your brand positioning is high-end or you want to differentiate your packaging, specialty paper is definitely worth considering. However, note that the print adaptability of specialty papers varies, requiring thorough communication with the manufacturer.

3. Handle Types: The Devil is in the Details

Handles are not only functional components of the paper bag but also important factors influencing overall aesthetics and comfort.

- Paper Rope Handle: Economical, environmentally friendly, commonly found on various paper bags, divided into flat paper rope and round paper rope.

- Flat Paper Rope: Lower price, but relatively weaker load-bearing capacity.

- Round Paper Rope: Stronger load-bearing capacity, more comfortable to hold, but slightly higher cost.

- My experience: If your budget is limited, or the product weight is not high, paper rope handles are a good choice.

- Cotton Rope Handle: Soft, comfortable, good texture, available in various colors and thicknesses, enhancing the paper bag’s grade.

- My experience: Cotton rope handles feel more approachable and natural, suitable for clients who value brand warmth.

- PP Rope Handle: Strong, durable, good gloss, strong load-bearing capacity, and moderate price.

- My experience: PP rope is the choice for pragmatists, offering high cost-effectiveness.

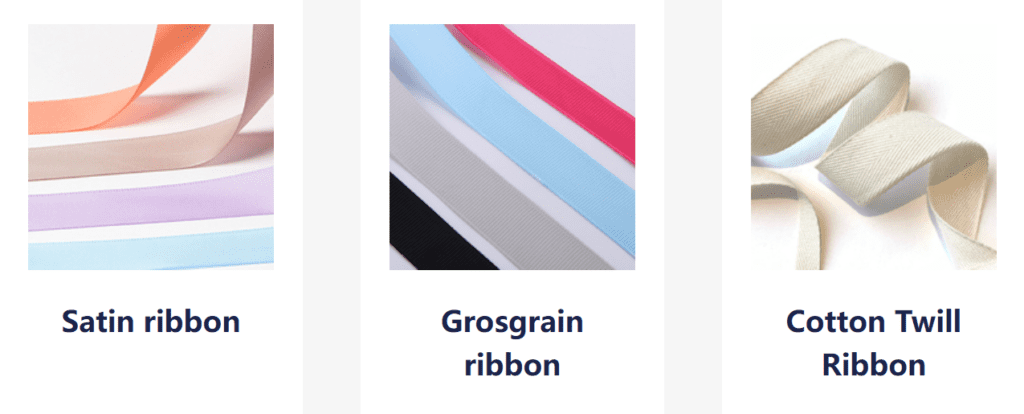

- Satin Ribbon Handle: Luxurious and elegant, usually used for high-end gift bags, smooth to the touch, and excellent visual effect.

- My experience: Satin ribbon handles instantly elevate the luxury feel of the paper bag, very suitable for gift or luxury product packaging.

- Punch Hole No Handle: This means the bag has no additional handle rope, only holes punched at the opening, allowing users to directly hold it through the holes or attach a ribbon or rope themselves. This design is often used for small gift bags, jewelry bags, or minimalist packaging.

- My experience: This design is perfect for a minimalist style or scenarios where consumers want to add their own decorations, but pay attention to the product weight, as it might affect carrying comfort otherwise.

When discussing handle choices with clients, besides considering aesthetics and cost, I also emphasize “load-bearing capacity.” I once had a client who, to save costs, chose thin paper rope handles with insufficient load-bearing capacity. As a result, the handles quickly broke after the products were loaded. This not only caused inconvenience for the client but also damaged their brand image. Therefore, in choosing handles, don’t be penny wise and pound foolish.

II. Printing Methods and Post-Press Processes: Bringing Your Design to Life

With a solid foundation, the next step is “dressing up” your paper bag – printing and post-press processing. This is a crucial step in transforming your design draft into a physical product and showcasing your brand’s personality.

1. Printing Methods: Presentation of Color and Detail

- Offset Printing: Also known as lithographic printing, it is the most common and mature printing method. It has high color reproduction, strong detail expression, is suitable for large-volume printing, and has relatively lower costs.

- My experience: If your design includes complex patterns, gradients, or requires high-precision color reproduction, offset printing is the first choice. Most custom paper bags use this method.

- Flexographic Printing: Uses environmentally friendly water-based ink, dries quickly, is suitable for rougher papers like kraft paper, and has strong expressive power for lines and text.

- My experience: Flexographic printing works great on kraft paper, especially suitable for simple logos and text printing.

- Screen Printing: Thick ink layer, high color saturation, suitable for special effects such as spot UV, gold/silver colors, etc.

- My experience: Screen printing has unique advantages in small batches and special effects. For example, if you want your logo to have a raised or sparkling effect, consider screen printing.

- Digital Printing: No plate making required, suitable for small batch, personalized, variable data printing, fast delivery, but relatively higher cost.

- My experience: If you only need dozens or even hundreds of paper bags, or if the content on each bag needs to be personalized, digital printing is the best choice.

I once had a client who needed a small number of paper bags with different participant names for an event. In this case, digital printing became the only solution. Although the unit price was higher, it saved on plate-making fees and met the personalized needs, which the client found very cost-effective.

2. Post-Press Processes: Enhancing the “Look” and “Feel” of the Paper Bag

After printing, a series of post-press processes can make the paper bag more attractive and enhance its quality.

- Lamination: A thin film is applied to the surface of the paper bag to provide waterproofing, scratch resistance, and add a glossy or matte effect.

- Gloss Lamination: Makes the paper bag surface shiny and colors more vibrant.

- Matte Lamination: Gives the paper bag surface a matte texture, understated luxury.

- My experience: Lamination is the “protective coat” for paper bags and is almost an essential process. It not only enhances the bag’s durability but also changes the overall visual effect.

- UV (UV Varnish): UV ink is applied locally or entirely to the paper bag surface and cured with ultraviolet light, resulting in a high-gloss, wear-resistant, and smooth-to-the-touch effect.

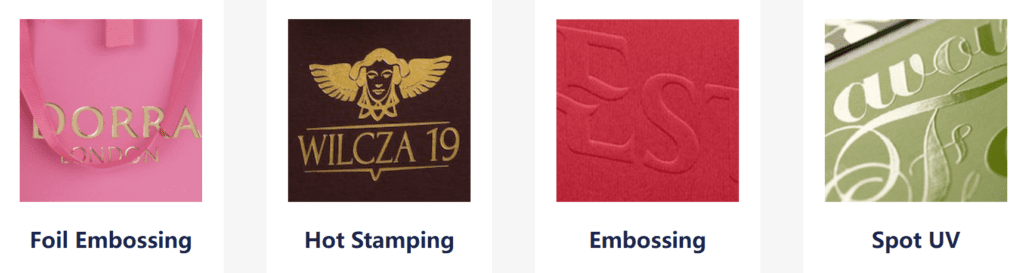

- Spot UV: Highlights specific elements in the design, such as a logo or text, giving them a raised or shiny effect.

- My experience: Spot UV is a magic touch to elevate the paper bag’s quality, creating a strong visual contrast and making your logo more eye-catching.

- Hot Stamping/Foil Stamping: Gold foil, silver foil, or other colored metallic foils are hot-pressed onto the paper bag surface, creating a metallic sheen effect.

- My experience: Hot stamping/foil stamping is a common process for high-end paper bags, instantly adding a touch of luxury. It is particularly common on some holiday gift bags or luxury product packaging.

- Embossing/Debossing: Patterns are created on the paper bag surface using a mold, making them raised (embossing) or recessed (debossing), adding a three-dimensional feel and tactile sensation.

- My experience: Embossing/debossing can give the paper bag a more artistic feel and unique tactile sensation, suitable for brands that pursue details and texture.

- Die-cutting: The paper is cut into specific shapes using a mold according to the design.

- My experience: Die-cutting can create irregularly shaped paper bags or special-shaped windows on the bag, adding fun.

These post-press processes are not about quantity but about selection based on your brand positioning, design style, and budget. A good custom printed paper bag is a perfect combination of printing and post-press processes, allowing your brand message to be presented to consumers in the most intuitive and attractive way.

III. MOQ and Production Time: Your Order, My Commitment

As an export factory, we deeply understand your concerns about Minimum Order Quantity (MOQ) and production time. These are key factors in determining whether you can smoothly launch your project and when you can receive your goods.

1. Minimum Order Quantity (MOQ): Tailored, Flexible Response

- Industry Standard: For custom paper bags, generally, the MOQ for offset printing is usually between 500 and 1,000 pieces. This is mainly because offset printing requires plate making, and plate-making fees are fixed. If the quantity is too small, the cost per paper bag will be very high.

- Our Flexibility: However, I understand that different clients have diverse needs. For some special situations, such as new brands testing the waters, small events, or needing a small number of samples to test market response, we will consider relaxing the MOQ, for example, 300 or even fewer.

- How is this achieved? This can usually be achieved by adjusting the printing method (e.g., using digital printing) or balancing costs. Of course, in this case, the unit price might be slightly higher than for large-volume orders.

- My suggestion: When inquiring, please clearly state your actual required quantity, and we will provide the most reasonable solution based on your specific situation.

I remember a startup owner who was just starting a high-end coffee business and only wanted to customize 200 paper bags as launch gifts. According to the standard MOQ, this quantity could not be accepted. But we optimized the production process and informed him that the unit price would be higher, ultimately helping him complete this small order. Later, his coffee business grew, and he became our long-term major client. This made me realize that sometimes, flexibility and a long-term perspective are more important.

2. Production Time: Efficient Operation, On-Time Delivery

- Design and Confirmation: After you provide the design draft, we will conduct a professional review and provide a design confirmation draft within 1-3 working days. This is to ensure that your design can be perfectly presented on the paper bag.

- Plate Making and Sampling: If sampling is required for confirmation, it usually takes 3-7 working days to complete sample production and delivery.

- Mass Production: After sample confirmation, mass production time will depend on the order quantity and process complexity.

- Regular Orders (500-5,000 pieces): Generally takes 10-15 working days.

- Large Volume Orders (over 5,000 pieces): May take 15-25 working days or longer.

- Special Processes: If complex post-press processes are involved (such as extensive hot stamping, die-cutting, etc.), production time may be extended accordingly.

- Shipping Time: This part depends on your receiving address and chosen shipping method (sea freight, air freight, express delivery) and is not within our production time scope, but we will assist you in arranging it.

- My commitment: We are always committed to improving production efficiency and shortening delivery times as much as possible without sacrificing quality. Upon receiving an order, we will give you a clear production schedule and maintain transparent communication throughout the production process, keeping you updated on the order progress.

I know how important time is for businesses. We once worked overtime to produce a batch of paper bags for a client who urgently needed them for an exhibition, and successfully delivered them one day before the exhibition. When the client sent a thank-you email, I felt genuinely satisfied. On the premise of ensuring quality, doing our best to meet the client’s delivery deadline is our responsibility.

IV. Samples and Quality Assurance: Seeing is Believing, Quality First

In the custom business, samples are an important bridge connecting the design draft to the final product, and quality assurance is the cornerstone of earning your trust.

1. Samples: Eliminating Doubts, Ensuring Perfection

- Importance of Samples: I strongly recommend that all custom orders, especially those with special processes or color requirements, include sample production. Samples allow you to:

- Visually feel the real size, material, and texture of the paper bag.

- Check whether the printing colors and patterns meet expectations.

- Confirm whether the effects of all post-press processes meet the requirements.

- Discover and correct potential problems before mass production.

- Sample Types:

- Digital Proof: Provided free of charge, it displays the design effect through images or PDF files, mainly used for checking design content and layout.

- Physical Sample: Usually requires a certain sample fee (specific cost depends on paper bag size, process, etc.), but in most cases, if there is a subsequent large order, the sample fee can be deducted from the payment. The physical sample is made exactly according to your custom requirements and is the closest to the final product.

- My suggestion: If time permits, be sure to produce a physical sample. This investment is worthwhile, as it maximizes the avoidance of dissatisfaction and rework risks after mass production.

I remember once, a client was very particular about the printing effect of a gradient color. We first made a digital proof, and the client felt it was fine. But I still advised him to make a physical sample. As a result, when the physical sample came out, the client found that the gradient transition was not as natural as expected. We promptly adjusted the printing parameters, and the colors of the final mass production were perfect. This once again proved the irreplaceable nature of physical samples.

2. Quality Assurance: Rigorous Control, Only for Excellence

As a professional export factory, we deeply understand that quality is the lifeline of an enterprise. We have a comprehensive quality management system to ensure that every link, from raw material procurement to final shipment, is strictly controlled.

- Raw Material Inspection: We only select high-quality paper, inks, and auxiliary materials from reputable suppliers. Each batch of raw materials undergoes strict quality inspection before warehousing.

- Production Process Control:

- First Article Inspection: Before production begins, quality inspectors conduct a comprehensive inspection of the first batch of products. Mass production proceeds only after confirmation.

- In-line Inspection: During the production process, quality inspectors regularly patrol the production line, conduct spot checks on product quality, and promptly discover and correct problems.

- Critical Node Control: Key processes such as printing, lamination, die-cutting, and bag gluing are closely monitored and data recorded.

- Finished Product Inspection: All products undergo 100% full inspection or random inspection before packaging to ensure no color difference, no damage, qualified size, and perfect craftsmanship.

- Packaging and Transportation: We use professional packaging methods to ensure the paper bags are not damaged during transportation.

- After-Sales Service: If you have any quality problems after receiving the goods, please contact us promptly, and we will investigate and provide a solution immediately.

Our pursuit of quality is ingrained in us. I often say that every custom paper bag with logo that leaves our factory represents our reputation. Over the years, we have passed multiple international quality certifications and established long-term stable cooperative relationships with brands worldwide, all stemming from our uncompromising commitment to quality.

V. Key Advantages: Choose Me, Choose Success

In a highly competitive market, our ability to stand out and earn the trust of numerous clients is no coincidence. Our advantages stem from our deep understanding of the industry and our precise grasp of client needs.

1. Experienced Industry Expertise and Professional Knowledge: Your Exclusive Paper Bag Consultant

- Two Decades of Dedication: My team and I have been deeply involved in the paper product export industry for over twenty years, accumulating rich production experience and professional industry knowledge. We understand the characteristics of various papers, the details of printing processes, and the preferences of different markets.

- Full Guidance: From initial design consultation and material recommendations to production process optimization and logistics arrangements, we can provide you with professional guidance and advice, helping you avoid pitfalls in the customization process.

- Problem-Solving Ability: Faced with complex designs or special requirements, we can quickly analyze problems and provide practical solutions.

I once encountered a client who had extremely high environmental requirements and wanted the paper bags to be completely biodegradable. This was a relatively new challenge at the time. Our team invested a lot of effort in researching biodegradable materials and inks and worked closely with suppliers, ultimately successfully producing fully biodegradable paper bags that met the client’s requirements. This problem-solving ability is a testament to our professionalism.

2. Advanced Production Equipment and Exquisite Craftsmanship: Hardware Guarantee of Quality

- Modern Factory: We own internationally advanced printing machines, laminating machines, die-cutting machines, automatic bag gluing machines, and other production equipment, ensuring production efficiency and product precision.

- Exquisite Craftsmanship: Our technical team is experienced and proficient in various printing and post-press processes, capable of perfectly transforming your design into reality.

- Technological Innovation: We constantly introduce new technologies and explore new materials to meet the growing demand for personalization and environmental protection in the market.

To do a good job, one must first sharpen one’s tools. Excellent equipment is the hardware foundation for us to produce high-quality custom paper bags. At the same time, our employees are skilled technicians who have undergone professional training, striving for excellence in every piece of paper and every detail.

3. Strict Quality Control System: From Raw Materials to Finished Products, Layer by Layer

- ISO Certification: We strictly adhere to ISO international quality management system standards, ensuring standardized and regulated production processes.

- Multiple Inspections: From raw material inspection and in-line inspections during production to comprehensive checks before finished products leave the factory, we implement multiple quality inspections to prevent unqualified products from leaving the factory.

- Traceability System: Every batch of products has detailed production records, enabling traceability of quality issues.

I often say that quality is not inspected out, but produced out. Our quality inspection system is not just about final checks but also about prevention and control throughout the entire production process.

4. Excellent Customer Service and Communication Efficiency: Your Trust, My Motivation

- Fast Response: Whatever your questions or needs, we will respond promptly.

- Transparent Communication: From quotation, design confirmation, production progress, to logistics information, we will maintain close communication with you, ensuring a worry-free experience throughout.

- Personalized Customization: We deeply understand and meet your personalized needs, providing one-on-one exclusive service.

- Long-Term Partnership Philosophy: We value not just individual orders but also hope to establish long-term stable cooperative relationships with you, becoming your trusted partner.

I have always believed that good communication is key to successful cooperation. I am happy to listen to every idea from our clients and will sincerely offer my professional advice. Often, our clients’ success is our greatest sense of achievement.

5. Competitive Pricing Advantage: Quality Products, Reasonable Costs

- Direct Factory: As a factory with a complete production line, we cut out intermediate links, allowing us to offer you more competitive ex-factory prices.

- Economies of Scale: Large-volume raw material procurement and efficient production management further reduce our production costs.

- Cost Optimization Suggestions: We will provide you with cost optimization solutions for different materials and process combinations based on your budget, maximizing your return on investment while ensuring quality.

While price is important, I hope you can see the “value” we provide. Our goal is to offer you products and services that are worth more than their cost, rather than blindly pursuing low prices at the expense of quality.

Conclusion: Your Brand Story Begins with a Perfect Custom Paper Bag

Custom personalized paper bags are more than just an order; they are about shaping a brand image. They carry your products and convey your brand spirit. As a veteran who has worked in this industry for over two decades, I know that every detail is crucial.

I hope that sharing my experience will provide you with some practical help on your journey to customizing custom paper bags. From choosing the right size and paper to selecting printing processes and understanding MOQ and quality assurance, every step is vital for the perfect presentation of the final product.

If you are planning to customize exclusive custom paper bags for your brand or have any questions about any of the above aspects, please do not hesitate to contact me. I am very happy to listen to your needs and use my professional knowledge and experience to help you create the custom paper bags with logo that best represent your brand image.

Looking forward to collaborating with you and embarking on a wonderful customization journey!